At Campus Valla in Linköping there is a unique building that was custom-designed for the electron microscope that materials researcher Lars Hultman uses. The microscope has such high resolution that it can take images of the space between atoms.

“The microscope is critical to our being able to maintain our position on the cutting edge of international research. Knowing exactly where basic elements are located helps us understand how materials function,” says Hultman.

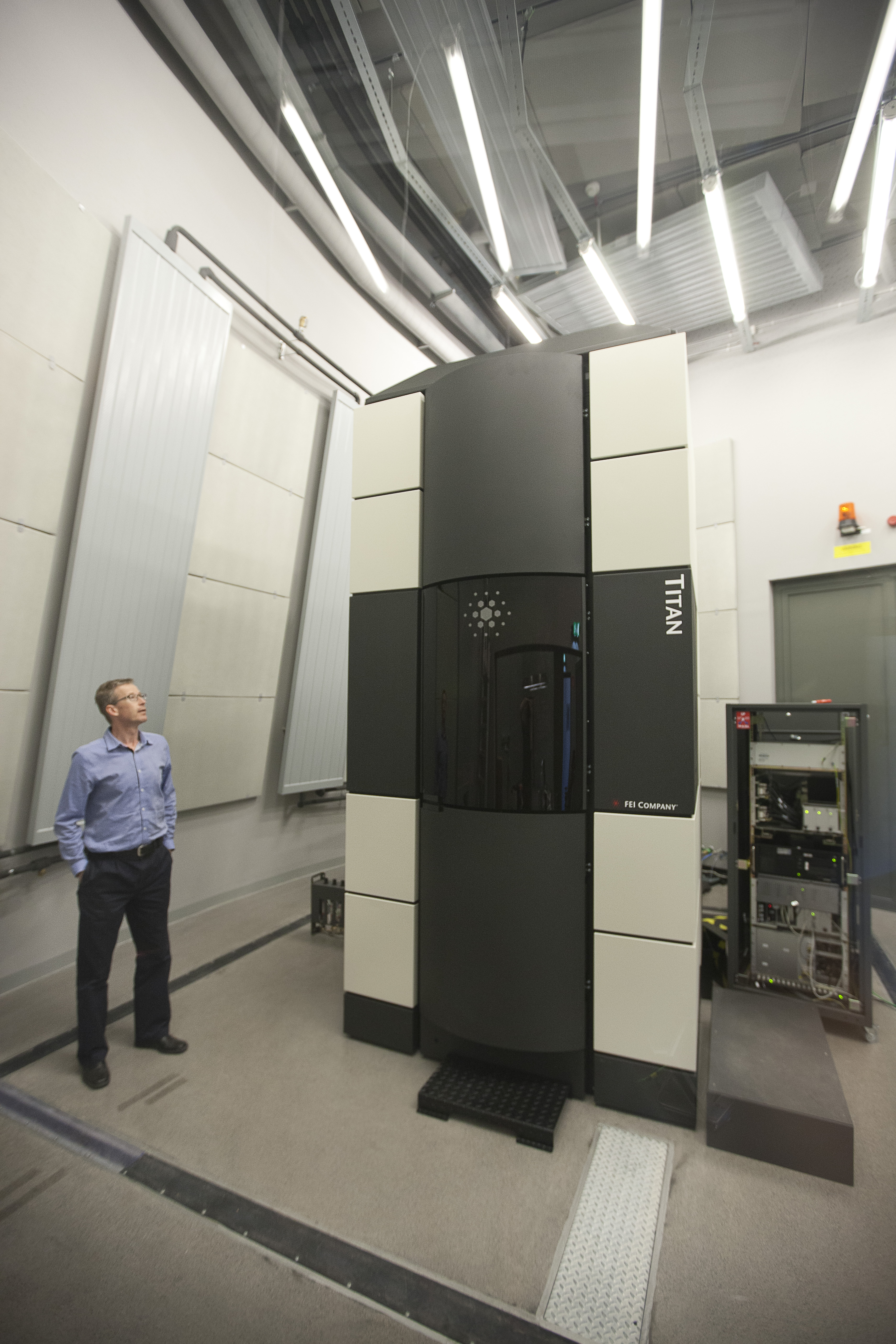

The microscope, which weighs 2.5 tons and is 3.7 meters high, is a transmission electron microscope. When it was inaugurated, in October 2011, it was one of Europe’s most powerful microscopes. It has a resolution of less than 0.7 Å, which roughly corresponds to the distance between two atoms in a silicon crystal.

With the sensitivity of an elf

The microscope was specially designed to look at new metals, ceramics, and semiconducting materials down to the level of the atom.

“We named the microscope Arwen after an elf in Tolkien’s trilogy about the Ring,” says Lars Hultman, professor of thin-film physics.

The association to elves is suitable, as they are regarded as the most gifted creatures in Tolkien’s world. They have a different perspective on the world and possess both sharper vision and hearing than any other being.

“The microscope is also extremely sensitive to low frequencies, such as the vibrations from cars,” says Lars Hultman.

The purchase of the microscope was made possible by a donation of SEK 46 million from the Knut and Alice Wallenberg Foundation in 2008. The Ångström Building, which houses the microscope, was financed in turn by Linköping University. The building itself is unique. The structure, which is set off by itself but is nevertheless on campus, is distinctive. The building’s shape and its façade, which is covered with titanium, are reminiscent of a tilted angel cake form with a hole in the middle.

No sources of error

The microscope stands in a specially designed

room with sloping walls to eliminate echoes.

Outside the glass walls there is a control room that looks like the one in Moonbase Alpha.

Outside the glass walls there is a control room that looks like the one in Moonbase Alpha.

“It’s important to eliminate all imaginable sources of error. We don’t tolerate vibrations. The temperature has to be steady, and we can’t have any air currents when we analyze samples. We have three shell shields of metal to prevent any disturbing magnetic fields,” says Lars Hultman.

Since the microscope’s shutter time is as long as a second, stability is absolutely crucial to the results. To obtain a stable base, the microscope stands on a foundation fastened to fissure-free bedrock.

The sensitivity of the microscope is so great that a person standing in the vicinity can disturb the sensitive measurements with his ferromagnetic blood, which is why it is remote-controlled from the control room.

How it works

From a “gun” at the top of the microscope an energy-rich electron beam is fired off. Further down there are a series of electromagnetic lenses that focus the beam into a tiny point where the electrons – accelerated nearly to the speed of light – impact the sample. Next to the sample there is an x-ray detector that registers what kinds of atoms are in evidence. At the bottom there is a spectrometer that measures how much energy the electrons lose on their way through the sample, data that reveal the chemical bonds. Thereby the scientists learn all there is to know about their materials – on the smallest possible scale.

The building also houses an ion slicer that the researchers use to make thick samples thinner.

In the coffee-break room a tapestry hangs, with the words “Unveiling the secrets of matter.”

“That’s what we’re trying to do,” says Lars Hultman with a smile. “The microscope enables us to study materials at the nano level in order to be able to create new ones. Everywhere there are surfaces that require their own special material properties, such as cutting tools, roller bearings, chemical sensors, solar cells, surgical implants, light diodes, and computer memories. Ongoing research and development entail that the demand for and uses for new materials will be ever greater and more numerous in the future.”

Text Carina Dahlberg

Translation Donald S. MacQueen

Photo Magnus Bergström