Wallenberg Scholar Maria Strömme is enlisting the help of nanotechnology to solve the global water supply problem. Her goal is to harvest water straight from the air using the sun’s rays and new nanomaterials.

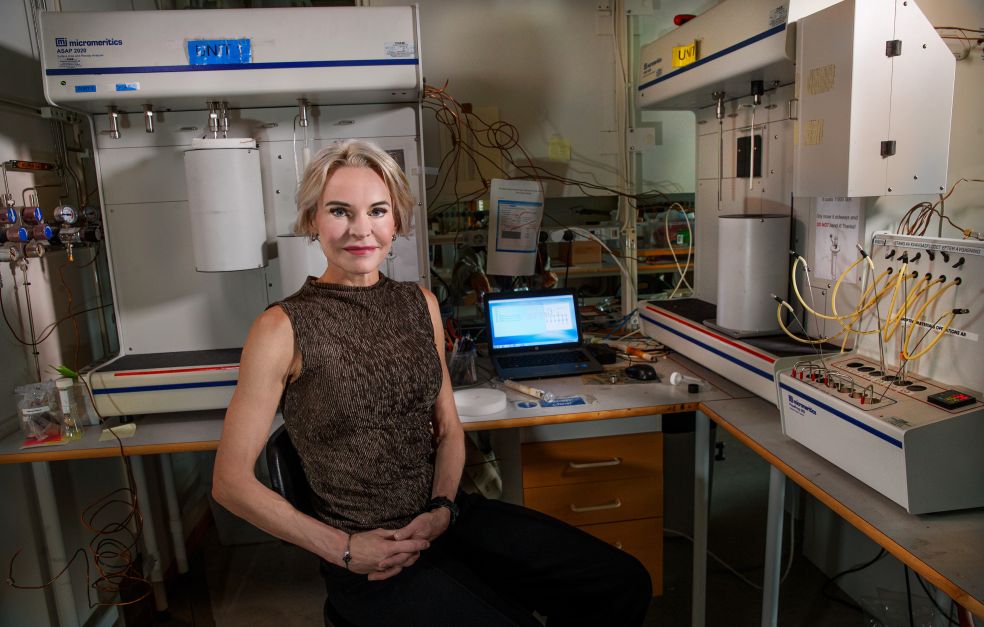

Maria Strömme

Professor of Nanotechnology

Wallenberg Scholar

Institution:

Uppsala University

Research field:

Nanomaterials science, especially porous materials and their use in environmental, energy and life-science applications

Floods and drought follow in the wake of climate change. By 2050 it is expected that more than half of the world’s population will have experienced water shortages a part of their daily lives. Harvesting water from the air might sound like science fiction, but, is actually already possible in a desert climate. But methods have so far required stable humidity and ready access to electricity.

Strömme intends to develop the technology so it can be used throughout the world, and without the need for electricity. It is further intended to develop systems that produce both drinking water and hydrogen. The path to this goal involves nanotechnology and new forms of “metal-organic frameworks.”

“The beauty of metal-organic frameworks is that they offer so many parameters that can be varied depending on what properties of the material are desired. It’s perfectly possible to design a material capable of storing hydrogen as well as carbon dioxide,” says Strömme.

The first metal-organic frameworks were fabricated as recently as the mid-1990s. The research field has expanded rapidly since then, and there are now more than 100,000 materials with tailored traits.

Catching gases

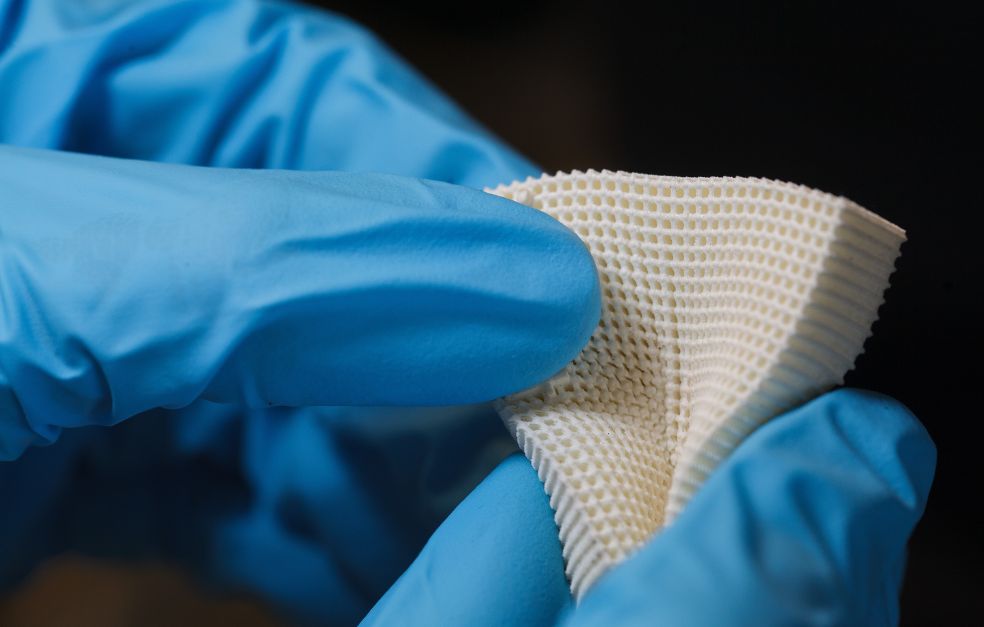

A metal-organic framework is an essentially solid but porous material made up of metal ions linked together with organic molecules to form a network. The network contains a large number of pores that can be filled with a wide range of other substances, such as gases or water molecules. Building frameworks has been likened to building with Meccano – but at nano level.

“It’s like having a box of toys that you can use to build virtually anything at all,” she says.

To date, researchers have concentrated on developing frameworks to separate and store various gases such as carbon dioxide and other greenhouse gases, and also to catalyze chemical reactions or refine metals. Strömme wants to use materials technology to help provide disaster relief.

Often the work doesn’t go at all as planned – things happen along the way that lead us in a completely different direction. And those are the projects that are the most fun of all.

“Our goal is to create fairly small units that can harvest water and also produce hydrogen for use in areas afflicted by disasters of various kinds. But the technology can also be used by people who want to become more self-sufficient,” she says.

Many parameters

In nanotechnology two main approaches are used to fabricate new materials. The first resembles the way a sculptor works – new materials are chiseled out with the help of electron beams, for instance. The second is more like the work of a traditional chemist: substances are mixed together to form new unique materials. Fabrication of metal-organic networks is an example of the latter approach.

“We’re feeling our way forward by changing parameters such as metals, heat, concentrations and solvents to design a nanostructure possessing the properties we desire at macro level.”

The work requires expertise in a number of disciplines. Her research team contains a broad range of specialists – chemists, pharmacists and engineers of various kinds. The materials already fabricated in the lab include structures that capture sulfur hexafluoride – a greenhouse gas – and also various photocatalytic structures. When these structures are struck by ultraviolet rays they can split water molecules into oxygen and hydrogen.

“Our goal is to arrive at a prototype that can harvest water in multiple cycles over a 24-hour period even in our northerly climate, where humidity varies over the day and night.”

Printing in situ

A further aim is to be able to fabricate the units using a new type of 3D printer. The technique is called binder jetting, and has been developed at the AM4Life center at Uppsala University. But Strömme stresses that a lot of scientific research and engineering work lies ahead if they are to succeed.

“We have a number of fundamental scientific questions that we must resolve along the path to application. But the driving force behind my research has always been to achieve practical utility,” she says.

When she was appointed professor at the age of 34 in 2004 she was the country’s youngest engineering professor. Some ten years later she was behind the discovery of a completely new ultra-absorptive material: Upsalite. On both occasions she found herself in the media spotlight. Since then she has been a guest speaker on the “summer talk” series on Swedish radio and spoken before world leaders at the World Economic Forum in Davos, Switzerland.

“The attention I’ve received has given me many new and interesting contacts. As a researcher, it’s important to gain an insight into the questions that others are wrestling with. Only then can we help to solve the various problems facing society and industry.”

Today, her role is to lead the research and provide the support needed so her research team can develop and make progress. But she sometimes misses her time as a PhD student, when she could spend hours in the laboratory working on the details of research.

“My job is my hobby – I can’t stay away from it. Every morning I wake up hours before the rest of the family so I have time to spend on what I like doing most.”

Text Magnus Trogen Pahlén

Translation Maxwell Arding

Photo Magnus Bergström