Project Grant 2012

Designed Nanoparticles by Pulsed Plasma

Principal Investigator:

Ulf Helmersson, Professor in Thin Film Physics

Co-investigators:

Linköping University

Igor Abrikosov

Magnus Odén

Lars Ojamäe

Nathaniel D. Robinson

Kajsa Uvdal

Umeå University

Ludvig Edman

Institution:

Linköping University

Grant in SEK:

SEK 38.3 million over five years

There is a bit of a magical shimmer over nanoparticles. If it were possible to match the particle’s design to the properties desired, the tiny particles could almost work like a magic spell and make things that seem like science fiction today into reality. At the same time that the great possibilities are emphasized, there is a concern that the knowledge of how the small particles affect health and the environment is still somewhat unexplored.

It was when Ulf Helmersson was listening to a 2006 lecture by Kajsa Uvdal, a colleague in a field close to his research at the time, where she expressed regret at not being able to use the nanoparticles as she wanted to, that the idea of how nanoparticles could be customized was born.

In 2008, Helmersson’s research team created their first tailor-made particle.

“We developed a method that is unique. We can make very specific particles and, in this context, relatively many of them that we can also place on a plastic surface. Today, particles can be purchased, there are relatively many who make particles, but applying them to a surface often causes problems,” says Ulf Helmersson in his office at Linköping University.

Control with plasma pulses

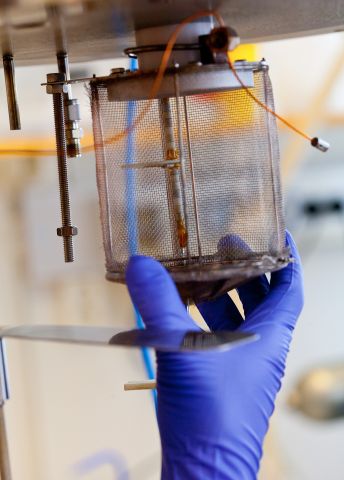

The secret behind the precise manufacture is that the research team can control the particles using plasma pulses.

During the lecture, Ulf Helmersson, who at the time worked with a plasma method for surface coating called high-power pulsed sputtering that provides a high degree of ionization of the coating atoms, began wondering if they could not be combined somehow.

“I had an idea that ionization of the atoms should improve the core formation and the growth of nanoparticle plasma. The idea proved unique and at that stage, we didn’t want to go public with it by seeking external funding. Instead, I went to Mille Millnert, the Vice-Chancellor at the time, who arranged an internal grant so we could conduct the first experiments and confirm that the idea was viable. Only then did we send in the first grant application,” says Helmersson.

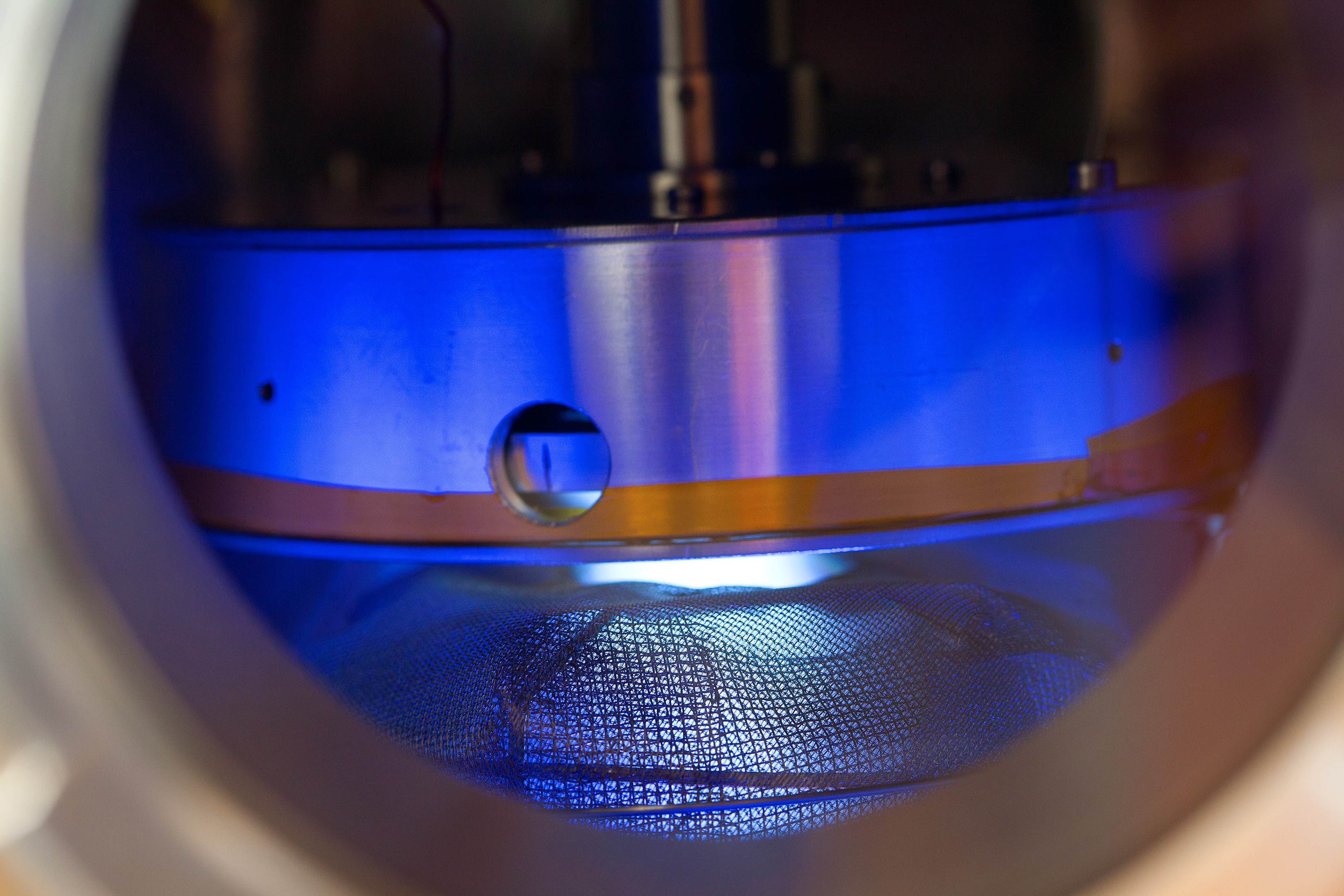

Plasma is ionized gas that exists naturally in, for instance, the Northern Lights and electric lightning, but also in fluorescent lamps, for example.

“Nanoparticles in plasma acquire a negative charge, which means that positive ions can effectively be gathered on the surface of the particle. This way, we can increase the rate of growth, but also work in the lab on various ions to create complex nanoparticles with different compositions in the core and the shell, or even with different shells like an onion.”

The major challenge is controlling the growth exactly the way one wants. But since Ulf Helmersson and his research team are specialized in creating surfaces of thin metal films using pulsed plasma technology, there is considerable knowledge in the field within the team.

“By varying the length, frequency and power of the pulses, we can guide and control the growth,” says Helmersson.

New green fuel

But there are a few catches, one being that it is important to design the right particle for the property one wants to achieve, which is not obvious. Another problem is creating an adequately large amount of particles.

“There are loads of applications for nanoparticles, it is important to set limits and choose the right area,” confirms Ulf Helmersson.

Consequently, the team is focusing on three areas: polymer light sources, nanoprobes in medicine - contrast radiography - and catalytic material.

“From the beginning, the hope was that the same particle could be used in all three areas. This has turned out to be too optimistic. For contrast radiography, specific nanoparticles are needs that are also after-treated in a special way. If we succeed, the method can be used for both imaging and treatment."

The third track, producing methanol fuel from carbon dioxide and hydrogen gas, is perhaps the most exciting.

“The difficulty is producing hydrogen gas in an economical and sustainable manner. There is a developed method, but it needs better catalytic material. We believe that we will be able to design such materials.”

Risk project

Being a researcher often means having to try to combine bold ideas with great patience.

“This is a risk project; we still do not know if our methods work well enough. Even if the idea is simple, it requires the right technical equipment and ability to solve all of the problems that arise along the way. It also proceeds painfully slowly; the experimental activities take an especially long time."

In parallel, and thanks to the research, Ulf Helmersson has also participated in the founding of several companies. At the end of 2013, he was appointed the entrepreneurial researcher of the year at Linköping University.

Text Carina Dahlberg

Translation Semantix

Photo Magnus Bergström